ワイヤーカット放電加工機Mitsubishi

MV2400R

ワイヤーカット放電加工機

Mitsubishi

MV2400R

製造年

2013

状態

中古

所在地

Mittweida

写真は示しています

地図を表示

機械に関するデータ

価格と所在地

- 所在地:

- 09 Mittweida, Deutschland

電話する

技術詳細

- ワーク重量(最大):

- 1,500 kg(キログラム)

- X軸移動量:

- 600 mm

- Y軸移動距離:

- 400 mm

- Z軸移動距離:

- 310 mm

- 全高:

- 2,150 mm

- 全長:

- 2,687 mm

- 全幅:

- 3,030 mm

- 総重量:

- 3,500 kg(キログラム)

- 装備:

- 冷却ユニット

オファーの詳細

- 広告ID:

- A20742257

- リファレンス番号:

- MPT-108

- 更新:

- 最終更新日:11.12.2025

説明

Wire-Cut EDM Machine

The machine comes from productive operation and is in fully functional, used condition. All relevant assemblies are complete; the generator cabinet, control system, wire feed, and AT system (Automatic Threader) are all present and complete.

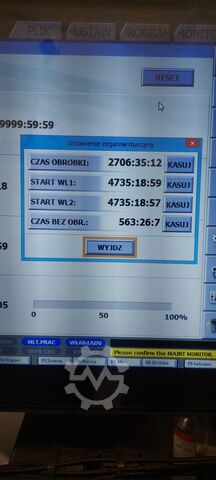

Running times according to control system:

Processing time: approx. 29,062 h

NC on-time: approx. 43,836 h

Ready-/TFT downtime: approx. 8,966 h

Maintenance records (excerpt):

Filter change: last performed at 176 h / 200 h

Resin change: 21 h / 1000 h

Oil refill: 742 h / 1000 h

Conductivity sensor: 742 h / 1000 h

Current supply rotation: 57 h / 80 h

The machine is complete but shows typical signs of use after more than 10 years in operation

Accessories are extensive and well organized

Servicing always confirmed as per control system

Automatic threading system included

Accessories / Equipment:

Original Mitsubishi nozzle & roller/bearing kit:

various guide rollers

upper and lower diamond guides

nozzle set (upper/lower nozzle)

drying stones / assembly tools

NSK/Japan replacement bearings

spare tension rollers

Manufacturer’s wooden box Mitsubishi Electric

Spare and consumables:

resin container (packed)

filter elements

quick adhesive components A/B

pH test strips

process chemicals (for EDM)

logbook / maintenance records

Documentation / manuals:

complete folders: Operator’s Manual MV Part 1 & 2

Psdjx Hadvjpfx Adlopl

training materials “Advance Series”

operating instructions (German)

maintenance and AT maintenance sheets

Travels (X / Y / Z):

600 × 400 × 310 mm

Working table / workspace:

table size: 840 × 640 mm (square table)

max. workpiece dimensions: 1050 × 800 × 295 mm

max. workpiece weight: 1,500 kg

Wire data:

wire diameter: 0.1–0.3 mm

max. wire feed: 23 m/min

tension: 0.5–25 N

automatic threading (AT), including fine-threading

Taper cutting:

opto-linear T/C device,

±75 mm (X/Y), max. taper angle 15° at 260 mm workpiece height

Generator / Control system:

transistor-controlled pulse generator

15" LCD touch control

6-axis simultaneous control

integrated 2D and 3D CAM (Parasolid viewer)

NC memory up to 1 GB

USB interfaces (2×)

Dielectric system

tank capacity: 860 l

filter flow rate: 50 l/min

paper filters (2 pcs)

resin container 10 l (ion exchanger)

この広告は自動翻訳されています。翻訳ミスがある可能性があります。

The machine comes from productive operation and is in fully functional, used condition. All relevant assemblies are complete; the generator cabinet, control system, wire feed, and AT system (Automatic Threader) are all present and complete.

Running times according to control system:

Processing time: approx. 29,062 h

NC on-time: approx. 43,836 h

Ready-/TFT downtime: approx. 8,966 h

Maintenance records (excerpt):

Filter change: last performed at 176 h / 200 h

Resin change: 21 h / 1000 h

Oil refill: 742 h / 1000 h

Conductivity sensor: 742 h / 1000 h

Current supply rotation: 57 h / 80 h

The machine is complete but shows typical signs of use after more than 10 years in operation

Accessories are extensive and well organized

Servicing always confirmed as per control system

Automatic threading system included

Accessories / Equipment:

Original Mitsubishi nozzle & roller/bearing kit:

various guide rollers

upper and lower diamond guides

nozzle set (upper/lower nozzle)

drying stones / assembly tools

NSK/Japan replacement bearings

spare tension rollers

Manufacturer’s wooden box Mitsubishi Electric

Spare and consumables:

resin container (packed)

filter elements

quick adhesive components A/B

pH test strips

process chemicals (for EDM)

logbook / maintenance records

Documentation / manuals:

complete folders: Operator’s Manual MV Part 1 & 2

Psdjx Hadvjpfx Adlopl

training materials “Advance Series”

operating instructions (German)

maintenance and AT maintenance sheets

Travels (X / Y / Z):

600 × 400 × 310 mm

Working table / workspace:

table size: 840 × 640 mm (square table)

max. workpiece dimensions: 1050 × 800 × 295 mm

max. workpiece weight: 1,500 kg

Wire data:

wire diameter: 0.1–0.3 mm

max. wire feed: 23 m/min

tension: 0.5–25 N

automatic threading (AT), including fine-threading

Taper cutting:

opto-linear T/C device,

±75 mm (X/Y), max. taper angle 15° at 260 mm workpiece height

Generator / Control system:

transistor-controlled pulse generator

15" LCD touch control

6-axis simultaneous control

integrated 2D and 3D CAM (Parasolid viewer)

NC memory up to 1 GB

USB interfaces (2×)

Dielectric system

tank capacity: 860 l

filter flow rate: 50 l/min

paper filters (2 pcs)

resin container 10 l (ion exchanger)

この広告は自動翻訳されています。翻訳ミスがある可能性があります。

これらの広告もご興味があるかもしれません。

小型広告

ドイツ

ドイツ

9,343 km

ワイヤーエローディングマシン

MITSUBISHIMV 2400R

MITSUBISHIMV 2400R

小型広告

Schömberg

Schömberg

9,391 km

マシニングセンター

HERMLEC30 U

HERMLEC30 U

小型広告

Bielawa

Bielawa

8,807 km

ワイヤ放電加工機(ワイヤカット放電加工機)

MitsubishiMV2400R

MitsubishiMV2400R

小型広告

Strassberg

Strassberg

9,376 km

ワイヤーエローディングマシン

MITSUBISHIMV 2400 R

MITSUBISHIMV 2400 R

小型広告

Bienne

Bienne

9,550 km

ワイヤ放電加工機(ワイヤーEDM)

CHARMILLESRobofil 440

CHARMILLESRobofil 440

小型広告

Herscheid

Herscheid

9,176 km

ワイヤーエローディングマシン

MitsubishiMV 2400 R

MitsubishiMV 2400 R

小型広告

スロベニア

スロベニア

9,255 km

ワイヤー放電加工機

Mitsubishi ElectricMV2400R

Mitsubishi ElectricMV2400R

小型広告

Lüdenscheid

Lüdenscheid

9,175 km

縦型マシニングセンター

DECKEL MAHODMU 50 T

DECKEL MAHODMU 50 T

小型広告

Halver

Halver

9,184 km

ワイヤー放電加工機

MitsubishiMV2400R

MitsubishiMV2400R

小型広告

Röthenbach an der Pegnitz

Röthenbach an der Pegnitz

9,166 km

ワイヤーエローディングマシン

MitsubishiDrahterodiermaschine MV 2400R

MitsubishiDrahterodiermaschine MV 2400R

小型広告

Karlsbad

Karlsbad

9,343 km

エローワ バイスパレットセットW

EROWAER-025895 , ER-054922 , ER-055774

EROWAER-025895 , ER-054922 , ER-055774

あなたの掲載は正常に削除されました

エラーが発生しました