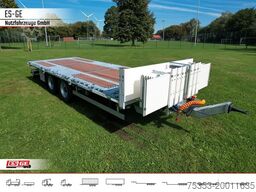

作業用プラットフォーム付きトレーラーES-GE

Tandem-Anhänger Bordwände, CV, Rungen

作業用プラットフォーム付きトレーラー

ES-GE

Tandem-Anhänger Bordwände, CV, Rungen

状態

新しい

所在地

Essen

写真は示しています

地図を表示

機械に関するデータ

価格と所在地

- 販売者所在地:

- Heegstraße 6-8, 45356 Essen, ドイツ

電話する

技術詳細

- 最大積載重量:

- 9,840 kg(キログラム)

- 総重量:

- 13,500 kg(キログラム)

- アクスル構成:

- 2軸

- 荷室長:

- 6,850 mm

- 荷室幅:

- 2,480 mm

- 装備:

- ABS(アンチロック・ブレーキ・システム)

オファーの詳細

- 広告ID:

- A20011635

- リファレンス番号:

- 36964

- 更新:

- 最終更新日:22.11.2025

説明

You can find our complete vehicle stock with immediately and short-term available vehicles on our website.

Excerpt from the equipment list. Complete specification available upon request.

Chassis:

* Steel welded construction with welded longitudinal beams and perforated Z-cross members

* Tight cross member spacing for high floor load capacity

* Ramp storage between the longitudinal beams behind the axle assembly

* Two insertion pockets for one loading ramp each located below the loading floor, with closing plate in the rear end frame

Front Support:

* Support winch with single-side operation

Drawbar Equipment:

* Height-adjustable rigid drawbar with bolted towing eye approx. 40 mm according to DIN

* Height adjustment +/- 150 mm

Rear Support:

* Two adjustable drop legs

Running Gear:

* 2 x 7 t air suspension axle assembly, make: SAF

* Drum brakes approx. 300 x 150 mm

* Wheel connection 10-hole, center-bolted for single tires

* Total air suspension lift approx. 180 mm, of which lift approx. 150 mm and lower approx. 30 mm

* Control via hand lever with latching function

Tyres:

* 4 x 285/70 R 19.5 – manufacturer at our discretion

* On 8.25 x 19.5 steel rims, manufacturer at our discretion

Splash Protection:

* PVC mudguards in front of and behind the axles

* In accordance with EU regulations with rear mudflaps

Load Securing:

* In the outer frame, a lashing rail for tension belts every approx. 200 mm, lashing force approx. 2.5 t

* 6 pairs of foldable lashing rings evenly distributed, lashing force approx. 8,000 daN

* Stake pockets for insert stakes 80/50

* 3 pairs of stake pockets in the outer frame, evenly distributed

* 4 rows of stake pockets transverse to the loading area, evenly distributed

Brake System:

* Air brake system according to EU regulations with EBS and a red/yellow coupling head each on the connection plate at the drawbar

* As a connection to the towing vehicle, a double-coil with 1 coupling head red/yellow and 1 duomatic coupling

* Spring-actuated parking brake acting on one axle

Floor:

* Approx. 28 mm Z-hardwood floor inlaid in the outer frame

* Wheel arch area with sheet metal covering

* Floor capacity: forklift driveable up to approx. 5 tons

Container Locks:

* Container locks for 1 x 20 ft. container according to ISO 1496, EN 284 or EN 452-1

* Additional container locks for 1 x 10 ft. at the front according to ISO 1496, EN 284, or EN 452

Lighting:

* Lighting system according to EU regulations, 24 Volt

* Multi-chamber rear lights, license plate lights, side marker lights, and contour marker lights at the rear

Gbjdpoxc Axxjfx Ag Ueg

* Connection plate at the drawbar including connecting cable with 15-pin and 2 x 7-pin plugs

Accessories included:

* 1 plug-in rotating beacon at the rear with registration for continuous light

* Additionally, with switch: 2 LED reversing lights at the rear on lamp bracket, operated via reverse gear

* Side and rear welded forklift bump stops

* 1 stainless steel toolbox each left and right behind the axles

* 6 x 25 cm side boards (3 per side) and front/rear wall made of anodized aluminum hollow sections, approx. 600 mm high

* Side boards foldable and removable, removable Kinnegrip stakes (internal width approx. 2,480 mm)

* Sideboard/stake magazine at the front on the front wall

* 1 additional mounting plate including parking sockets for air/electricity/EBS

Painting:

* Chassis hot-dip galvanized

* Side boards RAL 9010 Pure White

* Hubs KTL-Black

* Rear underrun guard RAL 9010 White

* Rims RAL 9006 Silver

* Vario

この広告は自動翻訳されています。翻訳ミスがある可能性があります。

Excerpt from the equipment list. Complete specification available upon request.

Chassis:

* Steel welded construction with welded longitudinal beams and perforated Z-cross members

* Tight cross member spacing for high floor load capacity

* Ramp storage between the longitudinal beams behind the axle assembly

* Two insertion pockets for one loading ramp each located below the loading floor, with closing plate in the rear end frame

Front Support:

* Support winch with single-side operation

Drawbar Equipment:

* Height-adjustable rigid drawbar with bolted towing eye approx. 40 mm according to DIN

* Height adjustment +/- 150 mm

Rear Support:

* Two adjustable drop legs

Running Gear:

* 2 x 7 t air suspension axle assembly, make: SAF

* Drum brakes approx. 300 x 150 mm

* Wheel connection 10-hole, center-bolted for single tires

* Total air suspension lift approx. 180 mm, of which lift approx. 150 mm and lower approx. 30 mm

* Control via hand lever with latching function

Tyres:

* 4 x 285/70 R 19.5 – manufacturer at our discretion

* On 8.25 x 19.5 steel rims, manufacturer at our discretion

Splash Protection:

* PVC mudguards in front of and behind the axles

* In accordance with EU regulations with rear mudflaps

Load Securing:

* In the outer frame, a lashing rail for tension belts every approx. 200 mm, lashing force approx. 2.5 t

* 6 pairs of foldable lashing rings evenly distributed, lashing force approx. 8,000 daN

* Stake pockets for insert stakes 80/50

* 3 pairs of stake pockets in the outer frame, evenly distributed

* 4 rows of stake pockets transverse to the loading area, evenly distributed

Brake System:

* Air brake system according to EU regulations with EBS and a red/yellow coupling head each on the connection plate at the drawbar

* As a connection to the towing vehicle, a double-coil with 1 coupling head red/yellow and 1 duomatic coupling

* Spring-actuated parking brake acting on one axle

Floor:

* Approx. 28 mm Z-hardwood floor inlaid in the outer frame

* Wheel arch area with sheet metal covering

* Floor capacity: forklift driveable up to approx. 5 tons

Container Locks:

* Container locks for 1 x 20 ft. container according to ISO 1496, EN 284 or EN 452-1

* Additional container locks for 1 x 10 ft. at the front according to ISO 1496, EN 284, or EN 452

Lighting:

* Lighting system according to EU regulations, 24 Volt

* Multi-chamber rear lights, license plate lights, side marker lights, and contour marker lights at the rear

Gbjdpoxc Axxjfx Ag Ueg

* Connection plate at the drawbar including connecting cable with 15-pin and 2 x 7-pin plugs

Accessories included:

* 1 plug-in rotating beacon at the rear with registration for continuous light

* Additionally, with switch: 2 LED reversing lights at the rear on lamp bracket, operated via reverse gear

* Side and rear welded forklift bump stops

* 1 stainless steel toolbox each left and right behind the axles

* 6 x 25 cm side boards (3 per side) and front/rear wall made of anodized aluminum hollow sections, approx. 600 mm high

* Side boards foldable and removable, removable Kinnegrip stakes (internal width approx. 2,480 mm)

* Sideboard/stake magazine at the front on the front wall

* 1 additional mounting plate including parking sockets for air/electricity/EBS

Painting:

* Chassis hot-dip galvanized

* Side boards RAL 9010 Pure White

* Hubs KTL-Black

* Rear underrun guard RAL 9010 White

* Rims RAL 9006 Silver

* Vario

この広告は自動翻訳されています。翻訳ミスがある可能性があります。

これらの広告もご興味があるかもしれません。

小型広告

Prigorje Brdovečko

Prigorje Brdovečko

9,238 km

作業台

SAFISCA 22 NISSAN CABSTAR 35.12 NT400

SAFISCA 22 NISSAN CABSTAR 35.12 NT400

小型広告

Prigorje Brdovečko

Prigorje Brdovečko

9,238 km

作業台

MULTITELALU 160

MULTITELALU 160

小型広告

Wiefelstede

Wiefelstede

8,980 km

重量運搬台車 5トン

KTSDSL

KTSDSL

小型広告

Prigorje Brdovečko

Prigorje Brdovečko

9,238 km

作業台

GSRB270T

GSRB270T

小型広告

Stahnsdorf

Stahnsdorf

8,830 km

作業台トレーラー

NiftyliftNiftylift 120 AC

NiftyliftNiftylift 120 AC

小型広告

Lemgo-Lieme

Lemgo-Lieme

9,056 km

オープントレーラー

PAVICTBPA18-66E TANDEM BAUSTOFF ANHÄNGER

PAVICTBPA18-66E TANDEM BAUSTOFF ANHÄNGER

あなたの掲載は正常に削除されました

エラーが発生しました