パイプ成形機、パイプ端加工transfluid Maschinenbau GmbH

UMR 642-CN

パイプ成形機、パイプ端加工

transfluid Maschinenbau GmbH

UMR 642-CN

製造年

2025

状態

新しい

所在地

Schmallenberg

写真は示しています

地図を表示

機械に関するデータ

価格と所在地

- 所在地:

- Schmallenberg, ドイツ

電話する

オファーの詳細

- 広告ID:

- A19563611

- 更新:

- 最終更新日:16.07.2025

説明

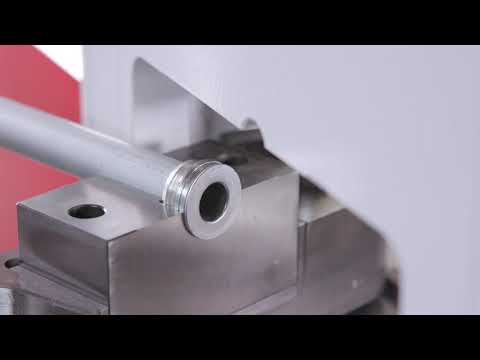

Tube flaring machine, hydraulic flaring machine, 37° flaring machine, 90° flaring machine, ORFS flaring, JIC flaring, tube end processing, flaring device, tube processing machine, rotary forming machine

Capacity:

- For tubes from 6 - 42 mm Ø

- Max. wall thickness (on tube-Ø 42 mm in steel) 4 mm

- Cycle time (adjustable per form/shape) 4 - 15 sec.

- Rotation/min 200

Machine equipment-/basic accessories:

- For end forming of tube with angle between 37° to 90° (dependent on tooling)

in one operation step via rotary principle

- Depending on the tube diameter, 180 ° bends with a clearance of

145 mm can be machined

- Length of the clamping dependent on tube size, approx. 1,0 x D

- Forming length dependent on tooling

- Operation and control via touch panel

- Start of operation via pushbutton

- Hydraulic forward movement, speed adjustable

- Electric adjustable length stop to control the required flare diameter

- Electric adjustable front feed of the tool holder

- Electric adjustable rolling time

- Clamping jaw can be swiveled, for easier loading of ORFS rings

- Integrated drawer for storage of tools

- Including transparent safety covers of the work area

- Standard norm electric and hydraulic equipment

- Machine stationary with underframe

- Colour RAL 7047 grey, RAL 3020 rot

Isdswzbc Nepfx Ah Isa

Drives:

- Clamping of the tube: servo-hydraulic

- Front feed tool holder: servo-hydraulic

- Rotation tool holder: electric

Machine data:

- Nominal pressure 250 bar, Operating pressure 200 bar

- Operating voltage 400 Volt - 50 Cyl. - 3 Ph. - 4,5 kW

The average consumption of the machine is approx. 1,8 kWh/h.

As the consumption is highly dependent on factors such as tube size and

geometry, speeds and power supply to the machine, it can only be used as a guide.

- Length 1230 mm

- Width 710 mm

- Height 1240 mm

- Weight approx. 800 kg

Capacity:

- For tubes from 6 - 42 mm Ø

- Max. wall thickness (on tube-Ø 42 mm in steel) 4 mm

- Cycle time (adjustable per form/shape) 4 - 15 sec.

- Rotation/min 200

Machine equipment-/basic accessories:

- For end forming of tube with angle between 37° to 90° (dependent on tooling)

in one operation step via rotary principle

- Depending on the tube diameter, 180 ° bends with a clearance of

145 mm can be machined

- Length of the clamping dependent on tube size, approx. 1,0 x D

- Forming length dependent on tooling

- Operation and control via touch panel

- Start of operation via pushbutton

- Hydraulic forward movement, speed adjustable

- Electric adjustable length stop to control the required flare diameter

- Electric adjustable front feed of the tool holder

- Electric adjustable rolling time

- Clamping jaw can be swiveled, for easier loading of ORFS rings

- Integrated drawer for storage of tools

- Including transparent safety covers of the work area

- Standard norm electric and hydraulic equipment

- Machine stationary with underframe

- Colour RAL 7047 grey, RAL 3020 rot

Isdswzbc Nepfx Ah Isa

Drives:

- Clamping of the tube: servo-hydraulic

- Front feed tool holder: servo-hydraulic

- Rotation tool holder: electric

Machine data:

- Nominal pressure 250 bar, Operating pressure 200 bar

- Operating voltage 400 Volt - 50 Cyl. - 3 Ph. - 4,5 kW

The average consumption of the machine is approx. 1,8 kWh/h.

As the consumption is highly dependent on factors such as tube size and

geometry, speeds and power supply to the machine, it can only be used as a guide.

- Length 1230 mm

- Width 710 mm

- Height 1240 mm

- Weight approx. 800 kg

あなたの掲載は正常に削除されました

エラーが発生しました