ユニバーサルマシニングセンターReiden

RX10-5X

ユニバーサルマシニングセンター

Reiden

RX10-5X

VB 消費税別

€330,900

状態

中古

所在地

Gütersloh

写真は示しています

地図を表示

機械に関するデータ

価格と所在地

VB 消費税別

€330,900

- 所在地:

- Dietrichstr. 103, 33335 Gütersloh, Deutschland

電話する

オファーの詳細

- 広告ID:

- A20125415

- 更新:

- 最終更新日:28.02.2026

説明

5-Axis Machining Center

with swivel milling head, pallet station, tool calibration, thermal compensation, work area extraction system, and much more.

Year of manufacture: 2016

Spindle hours approx. 1,500 h (after spindle replacement at the beginning of 2025)

Control System:

- Heidenhain iTNC 530 HSCI

- Heidenhain DCM Collision Monitoring

- Heidenhain HR 410 electronic handwheel

- Swiveling console with 19" monitor

- Teleservice via LAN/WLAN

Travel Range:

- Travel X 1,000 mm, Y 1,100 mm, Z 810 mm

- NC rotary table D 1,000 x 800 mm, swing diameter 1,350 mm

Milling Head:

- Automatic horizontal/vertical swivel milling head

- Fully-fledged stepless NC axis from -1° to +90°

- Blowing air through the spindle

- External coolant supply via nozzle ring

Drive power: 38 kW (100% duty cycle)

Speed: 16,000 rpm

Torque: 135 Nm at 40% duty cycle

Spindle interface: HSK 63-A

Media Supply:

- Internal coolant feed: 50 bar - capacity 28 l/min

- Paper belt filter with additional fine filter

- Individual tool pressure regulation during program operation

Tool Changer:

- Rack magazine with 73 stations (expandable with additional racks)

- Swiveling dialog operation panel

- Drawer for loading and unloading tools from tool racks

Tool Measurement:

- 3D wireless touch probe m&h 20.00-Multi, software adapted for HSK 63-A

- Including Kinematics-Opt, compatible with iTNC control, and calibration sphere on magnetic stand

Pallet Changer:

- Double palletizing unit, pallet diameter 1,000 x 800 mm, hole grid 100mm x 100mm, hardened drill bushes D 16mm

- Rotary table unit including zero-point clamping system, loading station accessible by crane

Cedpfjxhg Diex Af Aepw

- Pallet changer unit protected with enclosure

Special Equipment:

- Micro-Epsilon sensor

- For detection and dynamic compensation of thermal spindle growth

Chip Conveyor:

- Scraper belt conveyor along machine bed

- Chip ejection height 1,100 mm

Machine Enclosure:

- Full-area protective enclosure with large angle door for crane loading and a quick-access door

- Easy removal of swarf from the workspace

Extraction System:

- Oil and emulsion mist extraction, mechanical air filter, extraction capacity 1,800 m³/h

Rotating View Window:

- Viewing window integrated into the cabin door for workspace observation

Camera in Work Area:

- Monitor and keyboard at the operator console—allows monitoring of rear-side machining operations

Machine Data:

- Space requirement (without service area): approx. LxWxH 4,791 mm x 4,100 mm x 4,791 mm (including extraction system)

- Machine weight approx. 19,700 kg

- Total weight with all equipment plus maximum workpiece load, full tool magazine, and all operating materials: approx. 27,730 kg

- Connected load: 50 kVA, 400V, 50/60 Hz

This machining center, featuring an exceptionally good and practical configuration, is in very good condition. It operates with the renowned "Swiss precision." There is no service or repair backlog—in fact, the opposite. With an almost new milling spindle, the REIDEN RX 10 5X is well positioned for long-term use.

Technical modifications and errors excepted.

この広告は自動翻訳されています。翻訳ミスがある可能性があります。

with swivel milling head, pallet station, tool calibration, thermal compensation, work area extraction system, and much more.

Year of manufacture: 2016

Spindle hours approx. 1,500 h (after spindle replacement at the beginning of 2025)

Control System:

- Heidenhain iTNC 530 HSCI

- Heidenhain DCM Collision Monitoring

- Heidenhain HR 410 electronic handwheel

- Swiveling console with 19" monitor

- Teleservice via LAN/WLAN

Travel Range:

- Travel X 1,000 mm, Y 1,100 mm, Z 810 mm

- NC rotary table D 1,000 x 800 mm, swing diameter 1,350 mm

Milling Head:

- Automatic horizontal/vertical swivel milling head

- Fully-fledged stepless NC axis from -1° to +90°

- Blowing air through the spindle

- External coolant supply via nozzle ring

Drive power: 38 kW (100% duty cycle)

Speed: 16,000 rpm

Torque: 135 Nm at 40% duty cycle

Spindle interface: HSK 63-A

Media Supply:

- Internal coolant feed: 50 bar - capacity 28 l/min

- Paper belt filter with additional fine filter

- Individual tool pressure regulation during program operation

Tool Changer:

- Rack magazine with 73 stations (expandable with additional racks)

- Swiveling dialog operation panel

- Drawer for loading and unloading tools from tool racks

Tool Measurement:

- 3D wireless touch probe m&h 20.00-Multi, software adapted for HSK 63-A

- Including Kinematics-Opt, compatible with iTNC control, and calibration sphere on magnetic stand

Pallet Changer:

- Double palletizing unit, pallet diameter 1,000 x 800 mm, hole grid 100mm x 100mm, hardened drill bushes D 16mm

- Rotary table unit including zero-point clamping system, loading station accessible by crane

Cedpfjxhg Diex Af Aepw

- Pallet changer unit protected with enclosure

Special Equipment:

- Micro-Epsilon sensor

- For detection and dynamic compensation of thermal spindle growth

Chip Conveyor:

- Scraper belt conveyor along machine bed

- Chip ejection height 1,100 mm

Machine Enclosure:

- Full-area protective enclosure with large angle door for crane loading and a quick-access door

- Easy removal of swarf from the workspace

Extraction System:

- Oil and emulsion mist extraction, mechanical air filter, extraction capacity 1,800 m³/h

Rotating View Window:

- Viewing window integrated into the cabin door for workspace observation

Camera in Work Area:

- Monitor and keyboard at the operator console—allows monitoring of rear-side machining operations

Machine Data:

- Space requirement (without service area): approx. LxWxH 4,791 mm x 4,100 mm x 4,791 mm (including extraction system)

- Machine weight approx. 19,700 kg

- Total weight with all equipment plus maximum workpiece load, full tool magazine, and all operating materials: approx. 27,730 kg

- Connected load: 50 kVA, 400V, 50/60 Hz

This machining center, featuring an exceptionally good and practical configuration, is in very good condition. It operates with the renowned "Swiss precision." There is no service or repair backlog—in fact, the opposite. With an almost new milling spindle, the REIDEN RX 10 5X is well positioned for long-term use.

Technical modifications and errors excepted.

この広告は自動翻訳されています。翻訳ミスがある可能性があります。

これらの広告もご興味があるかもしれません。

小型広告

Warren

Warren

10,330 km

クランクシャフト研削盤

LandisLT2

LandisLT2

小型広告

Europa

Europa

8,565 km

CNC旋盤およびフライス加工センター

WFLM120 MILLTURN x 3000

WFLM120 MILLTURN x 3000

小型広告

Grüsch

Grüsch

9,448 km

マシニングセンター - ユニバーサル

DECKEL- MAHODMU100P duoBLOCK

DECKEL- MAHODMU100P duoBLOCK

小型広告

Gondelsheim

Gondelsheim

9,320 km

クレーンキャノピー クレーン屋内クレーン クレーン滑走路

Demag Portalkran KBK 250KGKBKI/II KBK1/2 8x4m 250Kg DC Kettenzug

Demag Portalkran KBK 250KGKBKI/II KBK1/2 8x4m 250Kg DC Kettenzug

小型広告

Mažeikiai

Mažeikiai

8,101 km

マシニングセンター

HERMLEC1200U

HERMLEC1200U

小型広告

Burscough

Burscough

9,364 km

ツールカッターグラインダー

HAASMultigrind

HAASMultigrind

小型広告

ドイツ

ドイツ

9,058 km

マシニングセンター

SW Schwäbische WerkzeugmaschinenBAW06-22

SW Schwäbische WerkzeugmaschinenBAW06-22

小型広告

West Yorkshire

West Yorkshire

9,305 km

ドウ・デバイダー

Mondial Forni Dough DividerSV Asda

Mondial Forni Dough DividerSV Asda

小型広告

Lemmer

Lemmer

9,115 km

門型フライス盤

MTorresMGP-51350 TT

MTorresMGP-51350 TT

小型広告

Korschenbroich

Korschenbroich

9,225 km

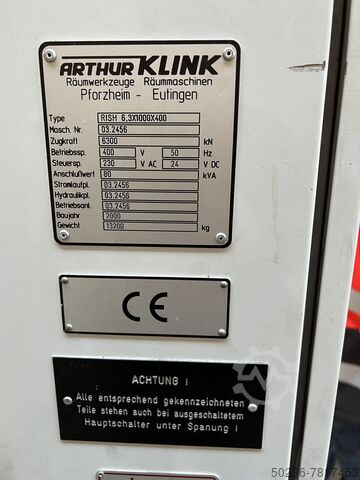

CNC内面ブローチ盤

Arthur KlinkRISH 6.3X1000X400

Arthur KlinkRISH 6.3X1000X400

あなたの掲載は正常に削除されました

エラーが発生しました