CNCマシニングセンターSCM

Morbidelli M100

CNCマシニングセンター

SCM

Morbidelli M100

製造年

2023

状態

中古

所在地

Nattheim

写真は示しています

地図を表示

機械に関するデータ

価格と所在地

- 所在地:

- Daimlerstr. 21, 89564 Nattheim, DE

電話する

オファーの詳細

- 広告ID:

- A20924487

- リファレンス番号:

- CC-K-25008

- 更新:

- 最終更新日:18.01.2026

説明

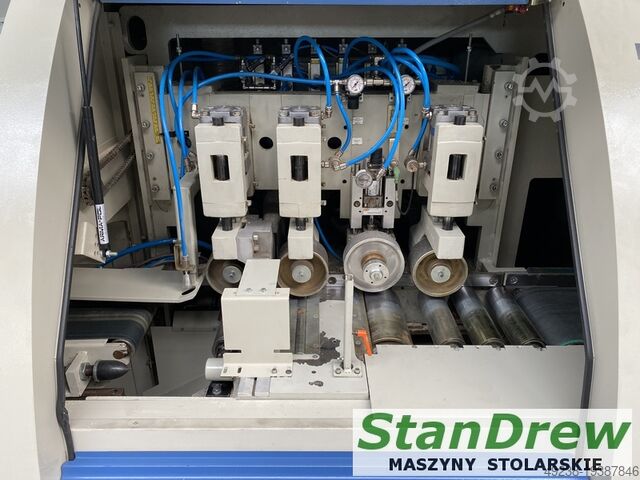

Exhibition Machine Garbsen CNC-CONTROLLED MACHINING CENTER morbidelli m100 Drilling and Milling Made for You! This numerically controlled machining center is equipped with a comprehensive range of accessories and tools for milling and drilling, enabling it to meet every requirement in the field of wood processing. Highly efficient – with drilling spindles reaching up to 8,000 rpm – and featuring technology that includes the most robust spindle available on the market, offering more than 1,000 hours of maintenance-free operation. Fully equipped – the suction cups can be individually configured with the TV FLEX worktable to adapt the machine precisely to your requirements. Easy and intuitive programming thanks to the integrated Cad-Cam MAESTRO CNC software. User-friendly operation is ensured by the lowered machine frame, which provides unrestricted access to the worktable at all times. The control cabinet and vacuum pump are integrated into the machine base, and the PRO SPACE variant requires no additional structural safety measures.

Robust Construction The supporting structure consists of an especially sturdy monolithic steel base, ribbed for stability and durability. The extra-wide bearing surface is purpose-designed to provide the machine with stability, ensuring constant precision in all working conditions. Anchoring to the floor is not required. The base forms a large, solid foundation for the moving gantry: the working unit is equipped with a balanced, stable, and resilient support, withstanding the highest stress, which ensures superior quality performance and greater accuracy. The moving gantry is a solid single piece anchored to the base, running on high-quality prismatic guides with ball bearing carriages. The working unit is mounted to this and moves along the Y and Z axes on prismatic guides with ball bearing carriages as well. Movement of the lower movable unit (X-axis) and the working unit along the gantry (Y-axis) is driven by a helical toothed rack and pinion system; this produces greater tooth-by-tooth thrust, achieving higher acceleration and increased speed on the X and Y axes. The specially designed helical gearing ensures reduced wear of mechanical components and quieter operation.

Ijdpfx Aex Twcisc Ajal

The vertical Z-axis is driven by a recirculating ball screw, providing perfect balance under dynamic load and withstanding significant acceleration and deceleration. The main milling unit is directly coupled to the Z-axis carriage, enabling superior surface finish quality as vibrations are completely eliminated. Travel along the X-Y-Z axes is achieved with brushless motors powered by static inverters. These provide:

- Reduced processing times due to improved acceleration

- Increased positioning accuracy due to high-resolution encoders

- Elimination of setup tasks at machine startup thanks to absolute encoders

- Elimination of general maintenance tasks, as the brushless system has no brushes

Axis movement management and general operation of the working elements...

この広告は自動翻訳されています。翻訳ミスがある可能性があります。

Robust Construction The supporting structure consists of an especially sturdy monolithic steel base, ribbed for stability and durability. The extra-wide bearing surface is purpose-designed to provide the machine with stability, ensuring constant precision in all working conditions. Anchoring to the floor is not required. The base forms a large, solid foundation for the moving gantry: the working unit is equipped with a balanced, stable, and resilient support, withstanding the highest stress, which ensures superior quality performance and greater accuracy. The moving gantry is a solid single piece anchored to the base, running on high-quality prismatic guides with ball bearing carriages. The working unit is mounted to this and moves along the Y and Z axes on prismatic guides with ball bearing carriages as well. Movement of the lower movable unit (X-axis) and the working unit along the gantry (Y-axis) is driven by a helical toothed rack and pinion system; this produces greater tooth-by-tooth thrust, achieving higher acceleration and increased speed on the X and Y axes. The specially designed helical gearing ensures reduced wear of mechanical components and quieter operation.

Ijdpfx Aex Twcisc Ajal

The vertical Z-axis is driven by a recirculating ball screw, providing perfect balance under dynamic load and withstanding significant acceleration and deceleration. The main milling unit is directly coupled to the Z-axis carriage, enabling superior surface finish quality as vibrations are completely eliminated. Travel along the X-Y-Z axes is achieved with brushless motors powered by static inverters. These provide:

- Reduced processing times due to improved acceleration

- Increased positioning accuracy due to high-resolution encoders

- Elimination of setup tasks at machine startup thanks to absolute encoders

- Elimination of general maintenance tasks, as the brushless system has no brushes

Axis movement management and general operation of the working elements...

この広告は自動翻訳されています。翻訳ミスがある可能性があります。

これらの広告もご興味があるかもしれません。

小型広告

ルーマニア

ルーマニア

9,329 km

SCM モルビデッリ M100

SCMMorbidelli M100

SCMMorbidelli M100

小型広告

Schwanberg

Schwanberg

9,195 km

サイジングソー

MARTINT60

MARTINT60

小型広告

Nattheim

Nattheim

9,278 km

CNCマシニングセンター

SCMMorbidelli M 100 (3-Achs)

SCMMorbidelli M 100 (3-Achs)

小型広告

Juszczyn

Juszczyn

8,726 km

傾斜スピンドルモルダー

Panhans240A

Panhans240A

小型広告

Wijchen

Wijchen

9,205 km

CNC横型マシニングセンター Morbidelli M100 2019

MorbidelliM100

MorbidelliM100

小型広告

Böblingen

Böblingen

9,338 km

テーブルルーター

Holzkraftminimax t 45c Tischfräse

Holzkraftminimax t 45c Tischfräse

小型広告

Bad Feilnbach

Bad Feilnbach

9,271 km

カンチレバーラック

Kragarmregal doppelseitig Höhe 4.160 mmTiefe je Seite 1.200 mm / Länge 4.000 mm

Kragarmregal doppelseitig Höhe 4.160 mmTiefe je Seite 1.200 mm / Länge 4.000 mm

小型広告

Nattheim

Nattheim

9,278 km

CNCマシニングセンター

SCM morbidelliM 400

SCM morbidelliM 400

小型広告

Miechucino

Miechucino

8,452 km

グレコン・ディムター OPTICUT 350 オプティマイザー

WEINIGDimter Opticut 350 R

WEINIGDimter Opticut 350 R

小型広告

Nattheim

Nattheim

9,278 km

CNCマシニングセンター

Format 4Profit H200 13.33 4-Achs

Format 4Profit H200 13.33 4-Achs

あなたの掲載は正常に削除されました

エラーが発生しました