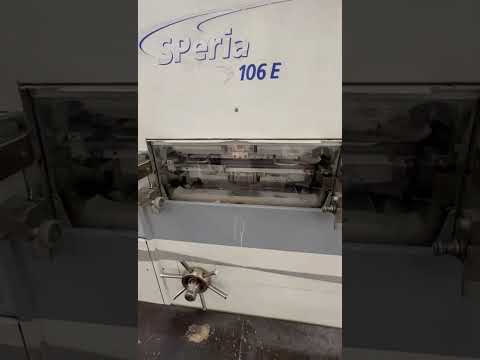

打ち抜き機Bobst

Autoplatine Speria 106 E

打ち抜き機

Bobst

Autoplatine Speria 106 E

製造年

2006

状態

中古

所在地

Hlavní město Praha

写真は示しています

地図を表示

機械に関するデータ

価格と所在地

- 所在地:

- Jezkova 1054/10, 13000 Praha 3, Česká republika

電話する

オファーの詳細

- 広告ID:

- A20248585

- 更新:

- 最終更新日:08.12.2025

説明

Bobst Autoplatine Speria 106 E

STANDARD EQUIPMENT

MACHINE

- Centerline system for quick job changeover.

- Electronic sheet travel monitoring system.

- Adjustable centering at the stripping station.

- Control cabinet air conditioning unit.

- Bobst electronic control system C.U.B.E. (Control Unit Bobst Electronic).

This microprocessor-based Bobst system allows the operator to easily manage, visualize, and monitor the machine’s various functions and components.

- Main motor with frequency inverter control.

Bsdpfexl Talsx Agwjcw

FEEDER

- Pile tray with handle for easy manual lateral alignment during production.

- Synchronization device ensuring proper sheet arrival to the front lays when the machine is stopped.

- Automatic pile lifting controlled by pressing foot.

- Rear pile guides (operator side and opposite operator side).

- Adjustable side blowers with Centerline markings.

- Suction unit.

FEED TABLE

- Feed table with anti-static stainless steel covering.

- Feed table entrance equipped with lateral ramps.

- Four front lays, pairwise adjustable, with front register control.

- "Pull" guide (operator side), adjustable with Centerline markings and side register control.

- Double sheet detector.

- Support plates at platen station entry.

- Sheet hold-down mechanism (guides sheets to front lays).

- Upper frame with manual lifting device.

- Upper transport system for paper, paperboard, and corrugated board.

- Transport belts with lateral guides and automatic tensioning system.

PLATEN

- Gripper reopening device.

- Centering and locking for equipment.

- Locking the chase to the upper beam.

- Cutting force measurement with strain gauge.

1 synthetic supporting plate.

1 upper chase: fixed bottom plate.

1 cutting plate.

WASTE STRIPPING STATION

- Air-cylinder-driven upper frame lifting.

1 upper pull-out frame (with crossbars and clamps).

1 lower pull-out frame.

DELIVERY

- Pile tray.

- Front jogger.

- Adjustable rear and side joggers with Centerline markings.

- Braking brush.

- Manual non-stop rack.

AVAILABLE EXTRAS

B MACHINE

1 B-1 Raised machine base

C FEEDER

1 C-4 Manual non-stop device

E PLATEN

1 E-5 Compensating plate

1 E-55 Micro-adjustable supporting plate centering

F WASTE STRIPPING STATION

1 F-31 Quick-lock device for the upper pull-out frame

この広告は自動翻訳されています。翻訳ミスがある可能性があります。

STANDARD EQUIPMENT

MACHINE

- Centerline system for quick job changeover.

- Electronic sheet travel monitoring system.

- Adjustable centering at the stripping station.

- Control cabinet air conditioning unit.

- Bobst electronic control system C.U.B.E. (Control Unit Bobst Electronic).

This microprocessor-based Bobst system allows the operator to easily manage, visualize, and monitor the machine’s various functions and components.

- Main motor with frequency inverter control.

Bsdpfexl Talsx Agwjcw

FEEDER

- Pile tray with handle for easy manual lateral alignment during production.

- Synchronization device ensuring proper sheet arrival to the front lays when the machine is stopped.

- Automatic pile lifting controlled by pressing foot.

- Rear pile guides (operator side and opposite operator side).

- Adjustable side blowers with Centerline markings.

- Suction unit.

FEED TABLE

- Feed table with anti-static stainless steel covering.

- Feed table entrance equipped with lateral ramps.

- Four front lays, pairwise adjustable, with front register control.

- "Pull" guide (operator side), adjustable with Centerline markings and side register control.

- Double sheet detector.

- Support plates at platen station entry.

- Sheet hold-down mechanism (guides sheets to front lays).

- Upper frame with manual lifting device.

- Upper transport system for paper, paperboard, and corrugated board.

- Transport belts with lateral guides and automatic tensioning system.

PLATEN

- Gripper reopening device.

- Centering and locking for equipment.

- Locking the chase to the upper beam.

- Cutting force measurement with strain gauge.

1 synthetic supporting plate.

1 upper chase: fixed bottom plate.

1 cutting plate.

WASTE STRIPPING STATION

- Air-cylinder-driven upper frame lifting.

1 upper pull-out frame (with crossbars and clamps).

1 lower pull-out frame.

DELIVERY

- Pile tray.

- Front jogger.

- Adjustable rear and side joggers with Centerline markings.

- Braking brush.

- Manual non-stop rack.

AVAILABLE EXTRAS

B MACHINE

1 B-1 Raised machine base

C FEEDER

1 C-4 Manual non-stop device

E PLATEN

1 E-5 Compensating plate

1 E-55 Micro-adjustable supporting plate centering

F WASTE STRIPPING STATION

1 F-31 Quick-lock device for the upper pull-out frame

この広告は自動翻訳されています。翻訳ミスがある可能性があります。

これらの広告もご興味があるかもしれません。

小型広告

Leinfelden-Echterdingen

Leinfelden-Echterdingen

9,330 km

FGT Graphic Machinery - デジタルプレス

Konica Minolta6120

Konica Minolta6120

小型広告

Alkmaar

Alkmaar

9,168 km

パンチングマシン

KAMAProcut 58

KAMAProcut 58

小型広告

ドイツ

ドイツ

9,058 km

製袋機

Honsel & Co.722

Honsel & Co.722

小型広告

София

София

9,059 km

オフセット印刷機

HeidelbergSM 74 5 P2 L

HeidelbergSM 74 5 P2 L

小型広告

ドイツ

ドイツ

9,058 km

2色

HeidelbergSM 52-2

HeidelbergSM 52-2

小型広告

Henstedt-Ulzburg

Henstedt-Ulzburg

8,857 km

紙断裁機

PolarN 115 PLUS

PolarN 115 PLUS

小型広告

スロベニア

スロベニア

9,286 km

オフセット版処理装置

Glunz & JensenTiger 125 Premium

Glunz & JensenTiger 125 Premium

小型広告

Alsfeld

Alsfeld

9,148 km

自動パンチングマシン

BobstSP142ER

BobstSP142ER

小型広告

Valea Mare-Podgoria

Valea Mare-Podgoria

8,799 km

オフセット印刷機

MAN Roland704

MAN Roland704

小型広告

Wuppertal

Wuppertal

9,192 km

テープ織機 4/42mm

Jakob Müller Frick AGNF42 4/42mm

Jakob Müller Frick AGNF42 4/42mm

あなたの掲載は正常に削除されました

エラーが発生しました